Winkelbohrspindel: The Hidden Powerhouse in Precision Machining

Introduction to Winkelbohrspindel

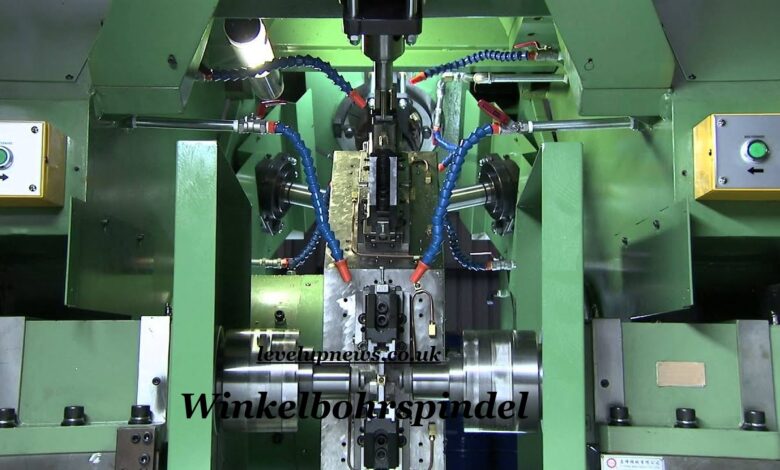

The term Winkelbohrspindel may sound technical and perhaps even a bit intimidating, but in reality, it refers to a highly practical and fascinating tool used in the world of precision machining. In English, it can be translated to “angle drilling spindle,” which already gives you a hint about its main purpose. It’s essentially a spindle attachment designed to allow drilling, milling, or machining operations to take place at different angles—especially when direct access is not possible.

Think about a situation where a machine needs to create holes in hard-to-reach corners or awkward spaces within a component. A standard vertical or horizontal spindle may not do the job effectively. This is where a Winkelbohrspindel comes into play. It bridges that gap by adding flexibility to machining processes, making it an indispensable tool in many industries.

Over the years, this tool has evolved from a niche accessory into an essential part of complex machining setups. With industries demanding higher precision and efficiency, the role of the Winkelbohrspindel has become more critical than ever. Let’s dive deeper into how it works, its applications, and why it’s such an unsung hero in manufacturing.

The Core Function of a Winkelbohrspindel

At its core, a Winkelbohrspindel is designed to redirect the drive force of a machine spindle at a defined angle—most commonly 90 degrees. This simple change in geometry opens up countless possibilities in machining. Instead of being restricted to drilling or milling on a flat, easily accessible surface, manufacturers can now tackle complex geometries, interior features, and hard-to-reach spots.

The magic lies in its construction. Inside a Winkelbohrspindel, you’ll find precision-engineered gears, bearings, and a carefully aligned housing that ensures minimal loss of power while transferring rotational motion. The high-quality versions of these spindles are built to handle heavy loads and maintain accuracy even under extreme working conditions.

It’s worth noting that different versions exist for different applications. Some are compact and lightweight for delicate operations, while others are robust and designed to endure heavy-duty drilling in hard materials. This adaptability makes the Winkelbohrspindel versatile enough to be used across industries like automotive, aerospace, mold-making, and even medical device manufacturing.

Why Manufacturers Rely on Winkelbohrspindeln

One of the primary reasons manufacturers turn to Winkelbohrspindeln is efficiency. In today’s competitive environment, saving time while maintaining high-quality output is non-negotiable. These angle spindles allow operations that would otherwise require multiple setups or even specialized machines to be completed in a single workflow.

For instance, imagine machining a complex engine block. There are numerous internal passages and tight areas where direct drilling is impossible. A Winkelbohrspindel allows the operator to drill those precise holes without removing the part from the fixture. This not only saves hours of setup time but also ensures consistency, since the part remains aligned throughout the process.

Another key factor is cost reduction. Instead of investing in entirely new machines or expensive custom fixtures, shops can simply add a Winkelbohrspindel to their existing CNC machine. This makes it a cost-effective solution for expanding capabilities without drastically increasing overheads.

Applications Across Different Industries

The applications of Winkelbohrspindeln are surprisingly wide. In the automotive industry, they are often used for drilling and milling in engine blocks, transmission housings, and other parts with complex geometries. Aerospace manufacturers rely on them for precision work on aircraft components, where space constraints and accuracy requirements are extremely high.

In the mold and die industry, these spindles are indispensable. Mold cavities often involve deep recesses or awkward angles that cannot be accessed with a standard spindle. With a Winkelbohrspindel, toolmakers can achieve the necessary detail without compromising on precision.

Even in medical technology, these spindles play a role. Producing implants, surgical instruments, and intricate device housings often requires micro-machining in tight spaces. Compact angle spindles provide the flexibility and accuracy needed to meet strict quality standards.

Advantages of Using a Winkelbohrspindel

When you look at the advantages, it’s easy to see why Winkelbohrspindeln are valued so highly. First and foremost, they enable access to areas that would otherwise be impossible to machine. This feature alone can open up entirely new design possibilities for engineers and manufacturers.

Another major advantage is increased productivity. By eliminating the need for multiple setups, these spindles reduce downtime and increase throughput. What might have taken several hours with part re-clamping can now be done in minutes.

Durability is also a strong point. High-quality Winkelbohrspindeln are engineered to withstand heavy loads, high rotational speeds, and continuous operation without significant wear. This makes them a reliable investment that can last for years with proper maintenance.

Challenges and Considerations

Of course, no tool is without its challenges, and the Winkelbohrspindel is no exception. One of the key considerations is the potential loss of power transmission due to the angle gears. While modern engineering minimizes this issue, it’s still something operators need to account for, especially in heavy-duty applications.

Another factor is alignment. Since the spindle is working at an angle, even slight misalignments can lead to inaccuracies in the finished part. This requires careful setup and calibration to ensure that the spindle performs at its best.

Finally, cost can also be a consideration. While they are generally more affordable than buying an entirely new machine, high-quality Winkelbohrspindeln still represent a significant investment. However, when weighed against the long-term productivity gains, the cost is usually justified.

The Future of Winkelbohrspindeln

Like most tools in modern machining, the future of Winkelbohrspindeln is being shaped by technology. With the rise of CNC automation, digital monitoring, and smart sensors, the next generation of spindles is likely to be more advanced, precise, and efficient.

Imagine a spindle equipped with sensors that constantly monitor torque, temperature, and vibration, feeding that data back to the CNC system in real-time. This would allow for predictive maintenance and ensure maximum performance without unexpected breakdowns.

Additionally, the push towards miniaturization in industries like electronics and medical technology will demand even smaller, more precise versions of these spindles. Manufacturers are already innovating in this direction, ensuring that Winkelbohrspindeln remain relevant for decades to come.

Conclusion

The Winkelbohrspindel might not be the most glamorous tool in a machine shop, but it’s undoubtedly one of the most important. By enabling access to difficult areas, improving productivity, and offering cost-effective versatility, it has earned its place as a cornerstone in precision machining.

For manufacturers looking to stay competitive, investing in a high-quality Winkelbohrspindel isn’t just an option—it’s a necessity. As industries continue to demand greater efficiency and accuracy, this humble spindle will remain a vital piece of the puzzle, quietly powering the future of modern manufacturing.